Silicone coaster molds have become increasingly popular among DIY enthusiasts and home decorators. These molds are made of high-quality silicone material. They can be used to create beautiful coasters in round and square shapes. They are easy to use and can be reused multiple times, making them an affordable and eco-friendly choice.

One of the main benefits of silicone coaster molds is their flexibility. They can be easily bent and twisted to release the coaster without damaging it. Moreover, the non-stick surface of the silicone mold ensures that the coaster comes out perfectly every time. Silicone molds are also heat-resistant.

Additionally, silicone molds are easy to clean. They are also simple to store. This makes them a convenient tool for any DIY project or home decor enthusiast.

Understanding Silicone Coaster Molds

Silicone coaster molds are an essential tool for making coasters/decorations in round and square shape. They are made of silicone, which is a flexible and durable material that can withstand high temperatures. In this section, we will discuss the features, benefits, and applications of silicone coaster molds.

Features of Silicone Coaster Molds

Silicone coaster molds are available in round and square shape, making them suitable for various coaster designs. They are made of food-grade silicone, which is safe to use and easy to clean. The molds are flexible, which makes it easy to remove the coasters without damaging them. Additionally, silicone coaster molds are heat-resistant and can withstand temperatures of up to 450°F.

Benefits of Silicone Coaster Molds

Silicone coaster molds offer several benefits over other types of molds. Firstly, they are durable and can last for a long time. Secondly, they are flexible, which makes it easy to remove the coasters without damaging them. Thirdly, they are easy to clean and maintain. Lastly, silicone coaster molds are versatile and can be used to make coaster/ decorations display.

Applications of Silicone Coaster Molds

Silicone coaster molds are used to make coasters for various applications, including home and commercial use. They are ideal for making coasters for hot and cold drinks. They can be used in restaurants, cafes, and bars. These coasters can display pictures or your brands. Silicone coaster molds are also popular among DIY enthusiasts who enjoy making their own coasters and decorative thing’s at home.

In conclusion, silicone coaster molds are a versatile and durable tool for making coasters/decorations in round and square shapes.

Benefits of Using Silicone Coaster Molds

Using silicone coaster molds has become increasingly popular in recent years due to their many benefits. Here are some of the advantages of using silicone coaster molds:

Easy to Use

Silicone coaster molds are very easy to use. They are flexible, non-stick, and can be easily removed from the mold. This means that even beginners can create professional-looking coasters with ease.

Durable

Silicone coaster molds are very durable and can last for years with proper care. They resist heat, cold, and other elements. This makes them a great investment for anyone who wants to create long-lasting coasters.

Versatile

Silicone coaster molds come in a round and square shape, making them very versatile. They can be used to create coasters/decorations in a variety of shapes and designs, allowing for endless creativity.

Easy to Clean

Silicone coaster molds are very easy to clean. They can be washed with soap and water or put in the dishwasher for easy cleaning.

Cost-Effective

Silicone coaster molds are very cost-effective. They are affordable and can be reused multiple times. This makes them a great investment for anyone who wants to create multiple sets of coasters.

Overall, using silicone coaster molds is a great way to create professional-looking coasters with ease. They are durable, versatile, easy to clean, and cost-effective, making them a great investment for anyone who loves to create.

How to Use Silicone Coaster Molds

Preparation

Before using a silicone coaster mold, it is important to prepare it properly. First, make sure that the mold is clean and dry. Then, apply a thin layer of mold release spray. Alternatively, you can use an alcohol wipe. This helps to prevent the coaster from dust sticking inside the mold.

Pouring

To create a coaster using a silicone mold, mix together the desired amount of resin according to the mold. Then, add any desired colorants or additives and stir well. Carefully pour the resin mixture into the mold, filling it to the desired level.

Curing

Once the resin has been poured into the mold, it will need to cure for some time. The curing time will vary based on the type of resin. It also depends on the thickness of the coaster. Follow the resin mixer instructions for curing time, and make sure that the coaster is left undisturbed during this time.

Unmolding

Once the coaster has cured, it is time to remove it from the mold. Gently flex the mold to loosen the coaster, then carefully peel the mold away from the coaster. If the coaster is difficult to remove, place the mold in the freezer for a few minutes. This can help release it.

Using silicone coaster molds is a simple and effective way to create custom coasters/decorations for your home or business. First, guarantee proper preparation. Then focus on pouring, curing, and unmolding techniques. This way, you can create beautiful and functional coasters that will last for years to come.

Maintenance and Care of Silicone Coaster Molds

Silicone coaster molds are a great investment for those who enjoy entertaining guests. They are also perfect for anyone who wants to add a touch of personalization to their home decor. Still, to guarantee that these molds last for a long time, proper maintenance and care are essential.

One crucial thing to remember is to clean silicone coaster molds after each use. This can be done by washing them with warm water and soap or by placing them in the dishwasher. It is important to note that harsh chemicals and abrasive sponges should be avoided as they can damage the mold.

Another important aspect of maintenance is storage. Silicone coaster molds should be stored in a cool, dry place away from direct sunlight. This will prevent them from becoming brittle and cracking over time.

Furthermore, it is important to inspect the molds periodically for any signs of damage or wear. If the mold appears to be damaged, it should not be used.

When it comes to care, you must remember something important. Do not use silicone coaster molds with sharp objects. Do not heat them above their recommended temperature range. Doing so can cause the mold to warp or become damaged.

Silicone coaster molds can last for years with proper maintenance and care. They offer endless possibilities for creating personalized and creative coasters.

Common Issues and Solutions

Incomplete Curing

One of the most common issues with silicone coaster molds is incomplete curing. This can happen for a variety of reasons. These include improper mixing of the silicone, not enough curing time, or the temperature being too low. If the mold is not fully cured, it will be soft and tear or deform easily.

To avoid incomplete curing, follow the manufacturer’s instructions carefully. Make sure you use the correct ratio of silicone to catalyst. It’s also important to allow enough time for the mold to cure completely. This process can take anywhere from a few hours to a full day, depending on the type of silicone used. Finally, make sure the temperature is within the recommended range for curing.

Air Bubbles

Another common issue is the presence of air bubbles in the mold. These can cause imperfections in the finished coasters, like pits or bumps. Air bubbles can occur if the silicone is mixed too quickly or vigorously. They can also arise if the mold is not properly prepared.

Mix the silicone slowly and gently to prevent air bubbles. Try to avoid introducing too much air into the mixture. It’s a good idea to tap the mold gently on a flat surface. This helps release any trapped air after pouring the silicone. If air bubbles do occur, use a toothpick or similar tool to pop them. Then, smooth out the surface.

Sticky Surface

Sometimes the surface of the silicone coaster mold can become sticky or tacky, even after it has fully cured. This can be caused by several factors, including high humidity, improper mixing, or using too much catalyst.

To prevent a sticky surface, make sure to mix the silicone thoroughly and use the recommended amount of catalyst. It’s also important to work in a low-humidity environment if possible. If the surface becomes sticky, treat it with a light dusting of cornstarch. You can also use talcum powder to help reduce the tackiness.

Choosing the Right Silicone Coaster Mold

When it comes to choosing the right silicone coaster mold, there are a few important factors to consider. The following are some key considerations to keep in mind:

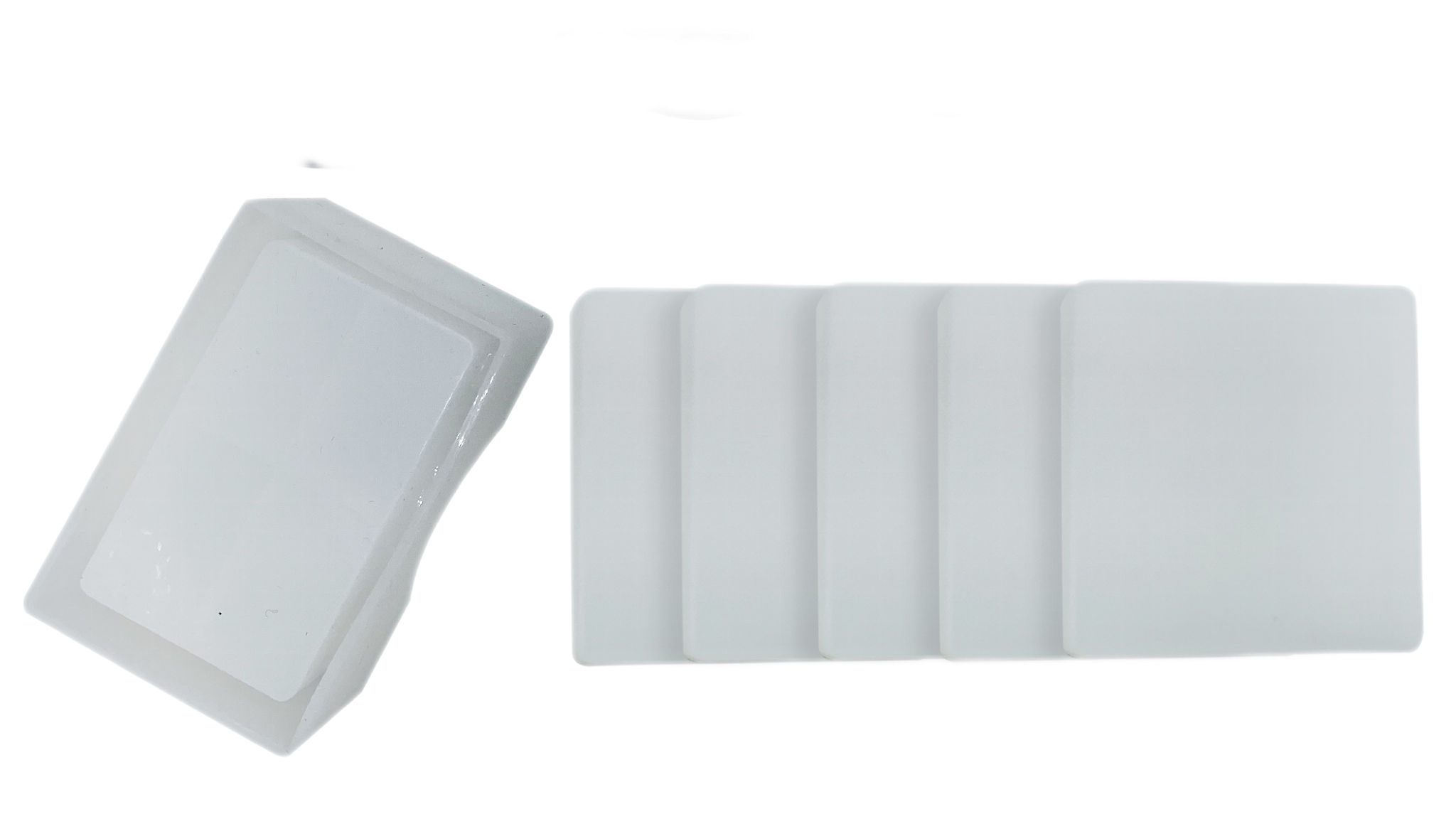

Size and Shape

The size and shape of the mold will decide the size and shape of your coaster. It’s important to choose a mold that will create a coaster that is the right size for your needs. Some molds are designed for larger, thicker coasters, while others are better suited for smaller, thinner coasters. Additionally, the shape of the mold will decide the shape of your coaster. Some molds are designed for square or rectangular coasters, while others are better suited for circular or oval coasters.

Material

Silicone coaster molds come in a variety of materials, each with its own benefits and drawbacks. It’s important to choose a mold made from a material that is appropriate for your intended use.

Design

Silicone coaster molds come in a variety of designs, from simple and plain to intricate and detailed. The design of the mold will decide the design of your coaster. It’s important to choose a mold with a design that you like and that fits your intended use. Some molds are designed to create coasters with a specific theme or style, like beach-themed coasters or vintage-style coasters.

Durability

Finally, it’s important to choose a silicone coaster mold that is durable and long-lasting. Look for a mold made from high-quality materials that can withstand repeated use without cracking or breaking. Additionally, consider the ease of cleaning and maintenance. A mold that is easy to clean and care for will last longer and provide better results over time.

Overall, choosing the right silicone coaster mold requires careful consideration of size and shape, material, design, and durability. By taking these factors into account, you can select a mold. It will create beautiful, long-lasting coasters. These coasters will meet your needs and exceed your expectations.

Advanced Techniques

For those who want to take their silicone coaster mold making to the next level, there are advanced techniques available. These techniques can create even more intricate and unique designs.

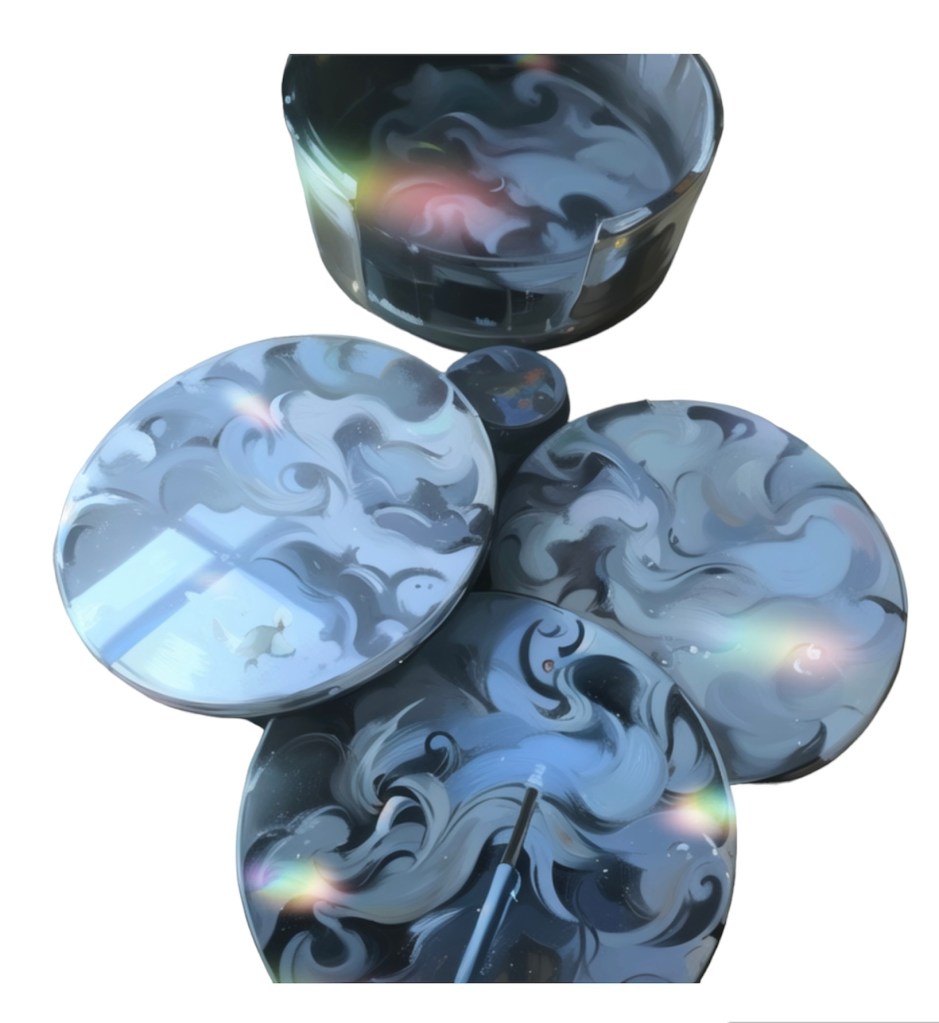

Adding Colors

One way to make your silicone coasters stand out is to add colors to the mold. This can be done by mixing in pigments or dyes with the silicone before pouring it into the mold. Not all pigments and dyes are compatible with silicone. Make sure to do your research before adding any colorants.

Embedding Objects

Another way to create interesting designs is to embed objects into the silicone. This includes small shells, stones, or even glitter. To do this, pour a thin layer of silicone into the mold first, then place the objects on top. Cover the objects with another layer of silicone and allow it to cure.

Layering

Layering is a technique that involves pouring multiple layers of silicone into the mold to create a three-dimensional effect. Start by pouring a thin layer of silicone. Allow it to cure. Then add another layer on top. Repeat this process until the desired thickness is achieved.

Using Molds Within Molds

For even more complex designs, consider using molds within molds. This involves creating a smaller mold within a larger one, then pouring silicone into both molds at the same time. The smaller mold can be removed once the silicone has cured, leaving behind a unique design.

Overall, these advanced techniques require more skill and experience, but can lead to some truly stunning silicone coasters.

Safety Precautions

When working with silicone coaster molds, you must take certain safety precautions. This ensures that the process is safe and free from any potential hazards. Here are a few safety tips that should be followed when using silicone coaster molds:

Wear Protective Gear

It is important to wear protective gear such as gloves and goggles when working with silicone coaster molds. This is because the silicone material can be sticky. It is difficult to remove from the skin. It can also cause eye irritation if it comes into contact with the eyes.

Work in a Well-Ventilated Area

When working with silicone coaster molds, ensure the area is well-ventilated. This helps avoid inhaling any fumes produced during the molding process. This is particularly important when using silicone that contains solvents, as these can be harmful if inhaled in large quantities.

Follow Mixer’s Instructions

It is important to follow the mixer’s instructions when working with silicone coaster molds. This involves using the correct amount of silicone. You should mix the material correctly. Allow it to cure for the recommended amount of time. If you do not follow these instructions, the mold may be of poor quality. It may also not be safe to use.

Keep Out of Reach of Children

Silicone coaster molds should be kept out of reach of children and pets. This is because the material can be harmful if ingested, and it can also cause choking if swallowed. Additionally, the molds can be sharp and pose a risk of injury if mishandled.

By following these safety precautions, users can ensure their experience with silicone coaster molds is safe. This helps keep the process free from any potential hazards.

Conclusion

In conclusion, Silicone coaster molds are a great investment for anyone who enjoys entertaining guests. They are also perfect for those who want to add a personal touch to their home decor. These molds are easy to use and can be customized to fit any style or theme.

One of the benefits of silicone coaster molds is their durability. They can withstand high temperatures and are resistant to damage from spills or scratches. This makes them a great choice for both indoor and outdoor use.

Another advantage of silicone coaster molds is their versatility. They can be used with a variety of materials, including resin, concrete, and clay. This allows for endless possibilities when it comes to creating unique and personalized coasters.

Silicone coaster molds are a worthwhile investment. They are perfect for anyone looking to add a touch of creativity to their home decor. With their durability and versatility, they are sure to be a useful addition to any household.

Start your DIY journey today and elevate your home decor with our high-quality silicone coaster molds.

Leave a comment